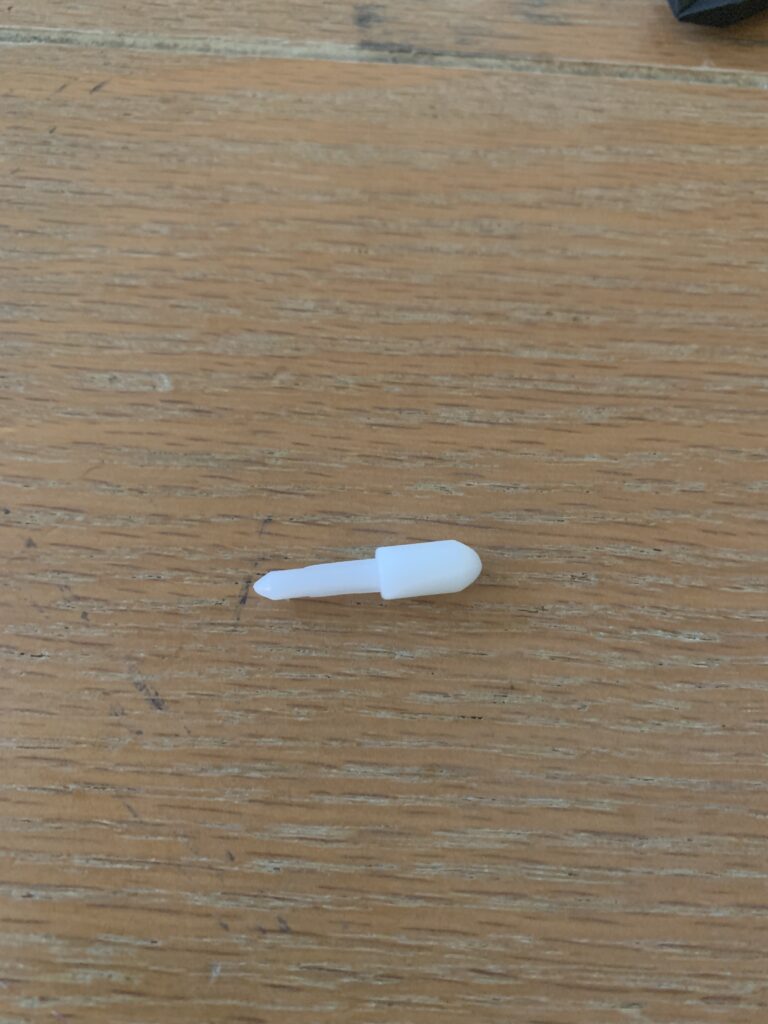

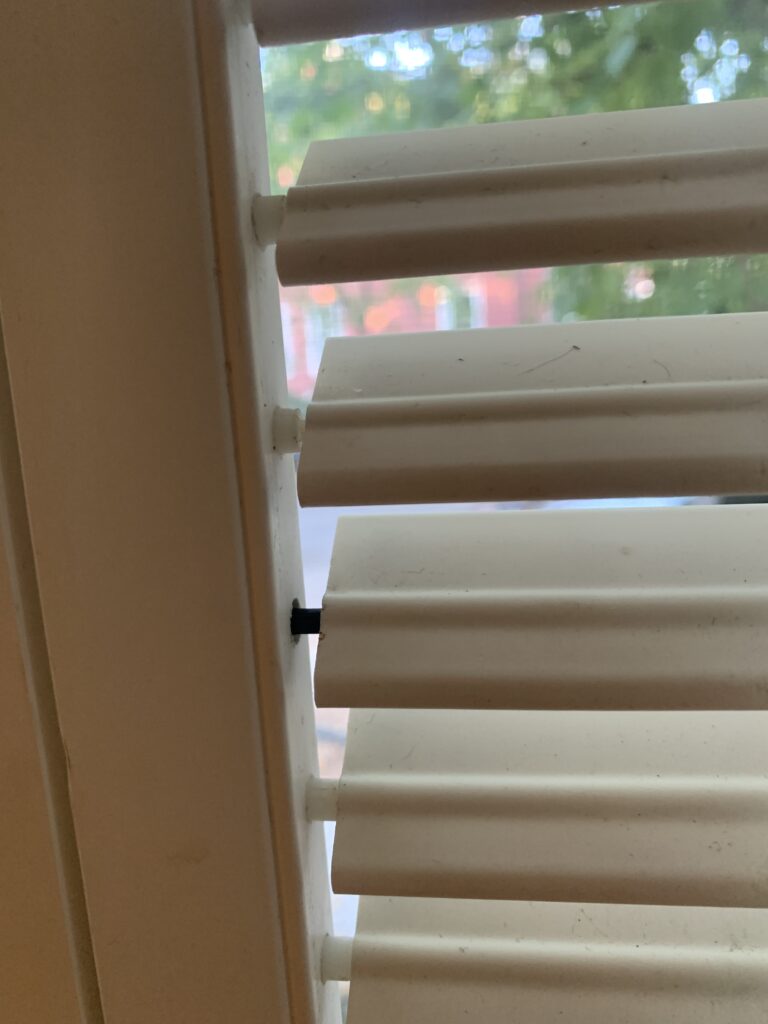

Let’s just say so many of them were out of place, but luckily we were only missing one of these:

Today’s daily creation was a simple one. I removed one of when current nubs (?)… I’ll call them nubs…and measured a few of its features. As you’ll see, I had to create one simple modification to allow me to 3D print them. I had to create a flat surface in the larger bottom portion flush with the small diameter upper portion. I’ll tell you why. As you see below, I tried printing in two different orientations. I knew that the nubs are experiencing a shear force and so I printed one of them horizontally to maximize strength, and the other vertically. Many of you might know this already, but the one printed horizontally has a larger surface layer contact which makes separating the layers much harder, aka can withstand some force. On the other hand, the one printed vertically has circular surface layers the size of the diameter and when a force is applied, could separate aka break. It’s a small part so the issue of layer separation isn’t a big one, but I wanted to flex my design skills.

All fixed up!

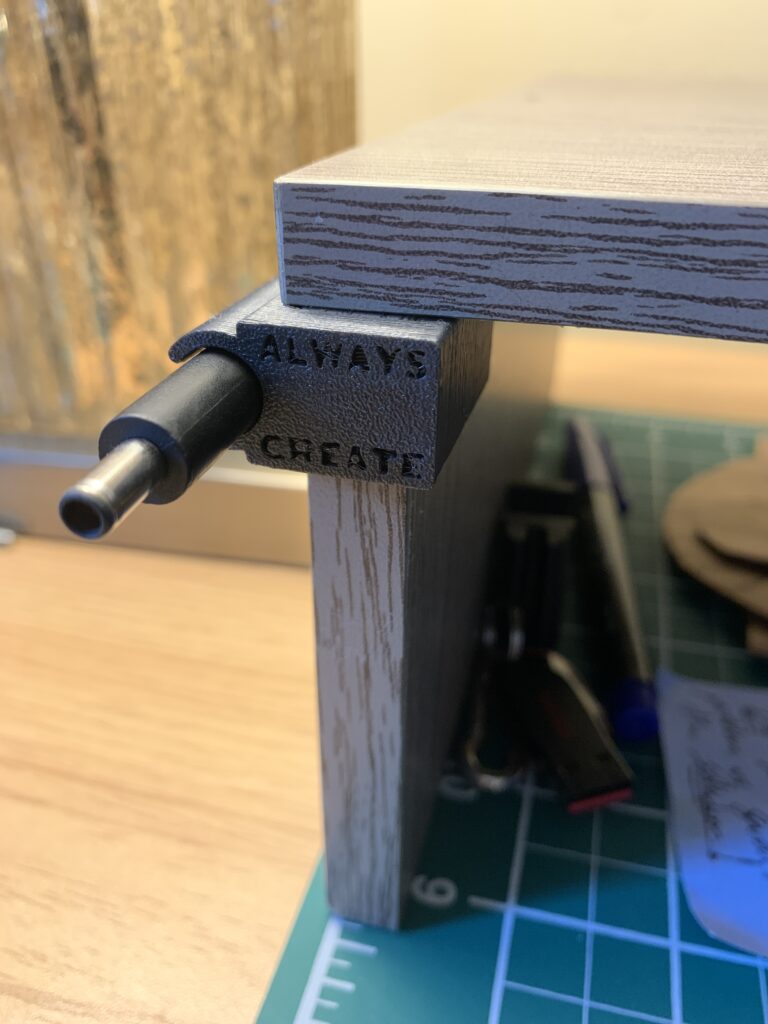

Window Blinds Fix was Designed Locally by Mario.